Automotive Semiconductors: EVs and Silicon Carbide

Silicon Carbide is one of the biggest changes in Automotive

You may recall seeing the below chart from my last piece:

The argument:

Premise 1: Vehicles that are more electrified require more internal semiconductors for power management purposes.

Premise 2: There will be more ‘highly electrified’ vehicles on the road by 2030 than ‘partially electrified’ vehicles.

Conclusion: This is an opportunity for semiconductor firms.

Let’s dig deeper into premise 1 and understand what’s driving increased electrification for power management. Then, we’ll take a look at one of the businesses with exposure to the tailwind.

Spoiler alert: it’s partially driven by silicon carbide and partially driven by more sensors.

Let’s start by understanding how EVs work.

How a Basic EV Engine Works

The video below does a good job at explaining things:

Of course, you’ll notice the profuseness of sensors in electric vehicles.

But apart from that, focus on the inverter in particular—the video calls it the “brain”—which converts power from DC to AC. Tesla doesn’t use a conventional inverter. Rather, Tesla EVs use Silicon Carbide inverters, which are one of the innovations, alongside improved battery technology, that makes modern EV mileage possible.

As an aside, Tesla obtains its inverters from the Swiss firm STMicroelectronics (NYSE:STM).

Silicon Carbide

Silicon carbide (chemical notation: SiC) significantly improves an inverter’s efficiency when translating power from DC to AC. By some measures1, a switch to SiC can extend the mileage of battery electric vehicles (BEV) by 5-10% and lessen the temperature issues associated with energy conversion.

The reason silicon carbide is used for this purpose is because of a special fundamental quality it possesses called a ‘wide bandgap’. This is discussed more in the appendix.

Now, the reason we aren’t using silicon carbide everywhere is simple: cost. Silicon carbide was historically priced at 10x the cost of conventional silicon for a number of reasons, including a notoriously difficult manufacturing process.

Nowadays, at certain price points and certain use cases (specifically applications that involve inverting a lot of electricity), silicon carbide components begin to make sense. After all, you’re not just getting the value of inverter efficiency, but also the cost savings from having a lower level of heat generation. This ultimately lowers the total cost of the vehicle.

So, to frame the scene: we have an expensive commodity product that’s difficult to process Manufacturers aren’t really paying attention to it because they don’t see demand in end-markets. And then all of a sudden—BOOM!—electric vehicles.

You know where this is going, right?

The Business Formerly Known As CREE

Cree, or since January 2021, Wolfspeed—no, it’s not a phase, mom—is the company that is going to change silicon carbide costs for the world. In doing so, it will drive EV adoption and meaningfully impact vehicle emissions.

Background

Before silicon carbide, Cree was already known for creating the first blue LED, which means we can thank them for modern-day video screens. Also, billboards.

Wolfspeed is uniquely positioned to take on the challenges of silicon carbide because bandgap distance is what defines the spectrum of light emitted in LEDs.

So the firm, as one of the largest global manufacturers of LEDs, has a long and storied history of making wide bandgap silicon, including silicon carbide and gallium nitride (GaN).

That expertise is now helping them pivot towards SiC and GaN production for automotive applications.

It’s a very sensible pivot. LEDs have become a commoditized business with low margins and intense capital demands. For a time, Cree was one of the few businesses out there where its ‘semiconductor materials’ segment gross margins were lower than its ‘device’ segment margins.

But, as we all know, where a business comes from is not where it is going. In fact, the name change from Cree (boring/bad/blue light LEDs destroyed my sleep schedule/definitely low margins) to Wolfspeed (bold/mysterious/self-driving cars?/definitely SaaS margins) was intentionally done to mark the switch from LEDs to semiconductors.

Management changes catalyzed this transformation. In 2017, Gregg Lowe, former CEO of Freescale, joined the business. Freescale was a semiconductor business focused on automotive applications, and Gregg, knowing the strategic value of the asset he was sitting on, pushed Cree towards the end markets of automotive and EV. He immediately started to shed assets and wind down non-core operations. This eventually culminated in the sale of the LED business to Smart Global holdings (SGH) in October 2020.

The remaining business bears little resemblance to what it was. As you may imagine, the trade-in of a hypercompetitive commoditized market for a larger and less populated one has been rewarded by investors accordingly.

Wolfspeed Today (Business Overview)

Post-divestiture, Wolfspeed will be focusing on three product segments: Materials (SiC and GaN), Power (SiC devices), and RF (SiC/GaN devices).

Materials are the sure bet, but the economics aren’t as good as the other two.

Both of the device businesses are more attractive, but success here is less certain because Wolfspeed will be competing against customers of its materials business.

SiC Materials Business

It’s safe to frame Wolfspeed as the “main character” of SiC. The demand here is difficult to ignore. However, while there are some technological processes that have high barriers to entry, the SiC materials space is only moderately defensible. That said, despite the likelihood of entry from firms like IIVI, Wolfspeed is currently the market leader and is directing meaningful investment towards increasing capacity.

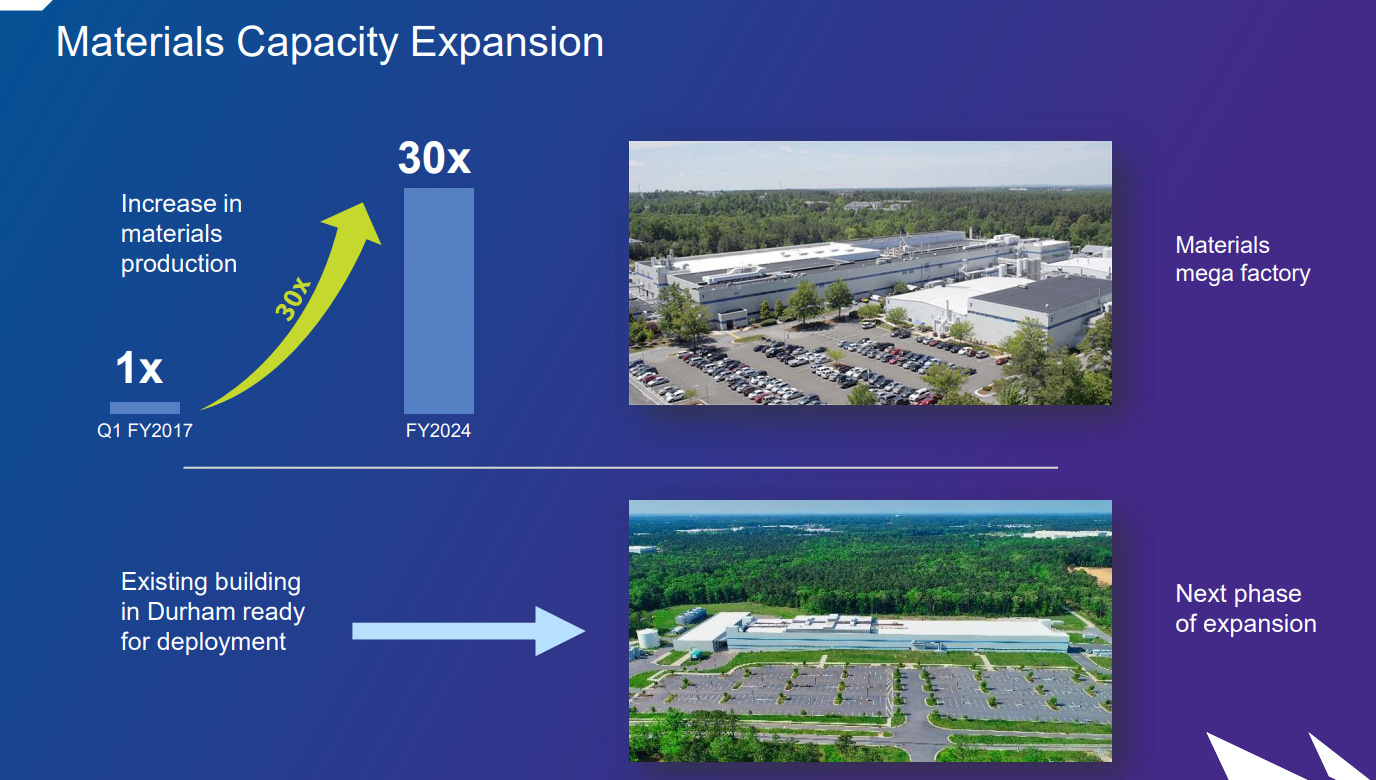

As seen below, Wolfspeed has outlined a plan to increase production by 30x in order to drive global adoption.

The firm has spent upwards of ~$1 billion dollars cumulatively to this end and has the most extensive background vs. peers in manufacturing SiC.

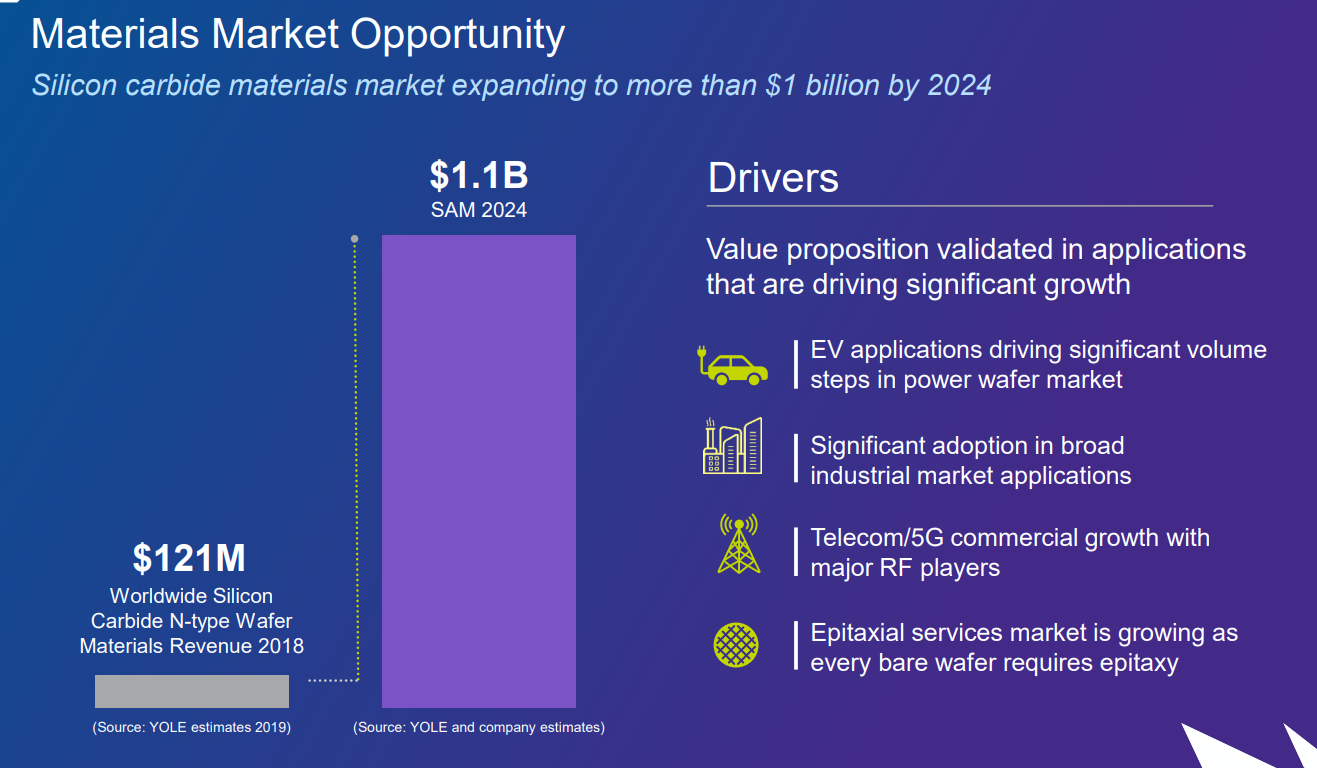

Despite the ~$1.1 billion SAM in 2024, Wolfspeed only guides to ~$600 million in materials. That assumes a paltry ~54% share, which is actually a slight market share loss compared to the present.

That comes off as somewhat conservative, but we can take 50%+ share as a safe assumption.

Wolfspeed also recently disclosed that the Mohawk Valley fabrication plant will dedicate its entire output towards 200mm SiC. That’s basically saying that it will be going all-in on the higher-margin process in the longer term at the cost of a near-term headwind. In other words, it’s a bet that the end market is going to be there by the time the plant is up and running.

That’s a bullish tell about the end state of SiC adoption and should be tipped as a belief that management is very comfortable with the end state happening sooner than they previously thought.

SiC Power Business

The power business is Wolfspeed’s efforts to bypass its materials customers and target the end-markets directly. Hard to say how this will turn out, as it’s clear that the firm is not a current leader in SiC design. As of now, STM/NXP/Infineon/On (discussed in follow-up pieces) are the clear winners or at least incumbents in this space.

However, Wolfspeed is positioning itself as the “Silicon Carbide Company”. The intention is to win the entire value chain. CEO Gregg brought this point home at the MS TMT conference:

But this whole supply chain issue that the auto industry is facing right now where car manufacturers have shut down production lines and so forth, that has now also sort of amplified the OEMs or the car manufacturers' attention to the supply chain and semiconductors and the attention to the supply chain in silicon carbide.

And here, we score super high marks. When I talk to the car manufacturers about silicon carbide, we start with where 60% of the world's supply of silicon carbide wafers. We're growing our silicon carbide wafer manufacturing capability by 30x over the next several years. We're building a mega fab in the state of New York. 11 months ago, that mega fab was ground and dirt. Today, it's a building that will move into production in less than a year.

I was just up in Mohawk Valley and visited that site last week. Tremendous amount of positive. Walk through the clean room. It's not a clean room yet, but walk through the ballroom, which will eventually be the clean room. Waffle floors up. Things are moving and in really very shape here. And so those car manufacturers look at us and they go, "Wow, this is a company that's investing in the fundamental technology of silicon carbide. They're putting in the world's largest silicon carbide fab. And by the way, they're going to ramp that at 200 millimeters or 8-inch as well." So we get a pretty solid checkmark when those OEMs look at the supply chain.

And again, we didn't forecast that there would be this strange dynamic in the auto semiconductor industry of the tremendous amount of demand overtaking the supply and having the supply demand issue here, but it certainly has come at a time where we look really smart, to be honest with you. Part of it, I will admit, it's a little bit luck. I mean we happen to be doing this at the time when that's happening. But this was our strategy from the outset, was to build a high-quality, high-capability wafer fab so we could begin ramping these customers.

Given that mindset and the existing lay of the land, Wolfspeed should see incremental victories in the SiC market.

Now, don’t think that the sales team will be scoring wins like Tesla car inverters anytime soon (STM owns this) but there may be green shoots in the lower price and relatively commodity-like areas, like off-the-shelf discrete SiC MOSFETs and Schottky Diodes2 for the most cost-conscious buyers.

The base case for automotive is that Wolfspeed devices will go into private-label providers on the low-end while being a materials supplier for higher-end automotive semiconductors. There will be some tension here eventually, but for now, SiC semiconductor companies don’t really have another choice for supply.

Also, Wolfspeed recently listed new automotive-qualified SKUs on its website that are somewhat competitive against STM’s non-discounted prices. The situation will continue to intensify—we might even see a move to direct distribution—as Wolfspeed bridges the gap and wins meaningful share.

The other nice thing is that the business should have a cost advantage by vertical integration. The salespeople will still be facing an uphill battle, but it’s a real benefit. There are a number of these sorts of small advantages that could translate into meaningful market penetration.

I’ll talk a bit more about SiC devices in the next automotive follow-up.

RF Power Business

This unit comes from Cree’s acquisition of Infineon’s RF Power business in 2018.3 The RF side of the market focuses on GaN-based devices. These devices oftentimes have GaN and SiC hybrid structures that benefit from both materials’ properties.

It’s really hard to fully gauge the benefit of GaN, but my assumption is that the secular growth story is just as strong, but with much less visibility.

I wouldn’t bet the house on the RF GaN opportunity, but it’s a meaningful opportunity.

Competitive Takeaway

Wolfspeed is the largest player in town. IIVI—an interesting, but less of a pure-play business—will ramp up capacity as well, but Wolfspeed will remain the global #1 SiC provider. The business benefits from being a fully integrated SiC provider, which should lower their COGS. I think it’s very easy to underwrite 50%+ share in SiC materials.

On the other hand, it’s uncertain if the devices business will win against the likes of NXP, STMicro, and Infineon. Given time and concerted effort, it’s not farfetched to believe that the firm will see some wins. I think it’s fair to assume the business can take a meaningful share, though that’s hard to ballpark.

Valuation

This is where the Wolfspeed thesis begins to see some problems.

Let’s start with the 2024 forecast released by CEO Gregg Lowe at the 2019 investor day. Management forecast highlights:

Wolfspeed revenues growing from $538M in 2019 to ~$1.5B in 2024 (~30% CAGR)

Gross Margin expanding from 46% in 2019 to 50-54% in 2024

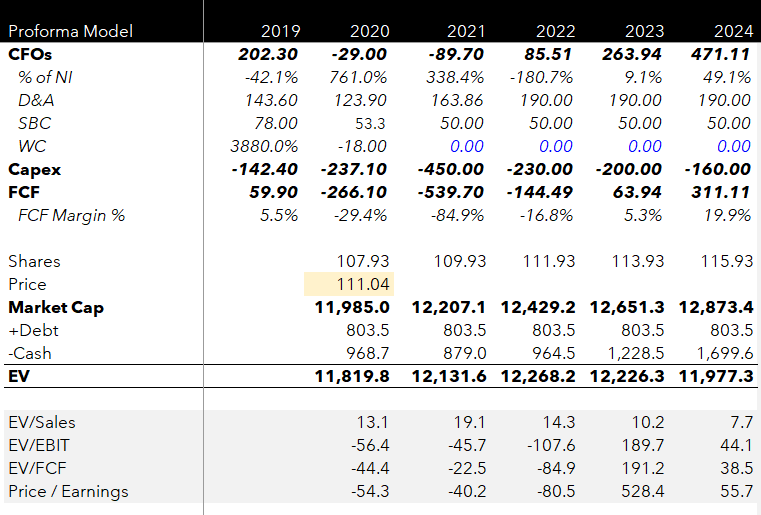

Free Cash Flow margin expanding from 5% in 2019 to ~20% in 2024

This was one hell of a guide and the share price essentially took it at face value. However, since then, there’s been incredible multiple expansion.

Let’s model this out.

Revenue

Aggressive growth to get us to management guidance of ~20% FCF margins in ~2024.

And a very dirty DCF

Politely: it seems somewhat imprudent to pay ~38x 2024 FCF for this business. I assure you that there are better risk/reward scenarios out there in semiconductor land.

But let’s stress test those aggressive growth assumptions. Specifically, let’s see if Wolfspeed can do more 2024 revenue than 2019 management estimates given what we know in 2021 about accelerating EV adoption.

As of August 2020, I would guess that this value is pretty close to 100%!

And, just given recent headlines, I get the sense EV adoption is accelerating. Just a few months ago, VW and GM announced that the majority of their vehicles sold will be EVs by 2030. That reads like EV expectations are being pulled forward.

When I last spoke with management, they said that their 2024 number assumed 5% penetration into EV.

Given what we know, there’s no way that’s true, which means one of two things:

They were being coy about their EV penetration assumptions, or

We’re about to see some ridiculous beat and raises over the next few years.

And, pulling the demand forward actually increases the Wolfspeed capture of the SiC industry revenue S-curve. The competition takes time to materialize, especially with such a complex process.

I believe that this is where the company can be “cheap”. And, given that it is a huge terminal value company, if this interest rate-related share price compression continues, there could be an incredible risk-reward scenario.

This is the biggest “what if” about this company. If this scenario were realized, it would certainly justify such a high price.

Ok, so let’s toy with the assumptions and assume that revenue is a lot higher, to the tune of ~$1.9 billion in 2024.

This almost works at today’s price (note the paltry 8% discount rate). You’re still paying ~25x 2024 EV/FCF, but that might be acceptable to some investors.

The takeaway here is that the terminal value has a lot of sensitivity and I believe most of it is to the upside.

Anyway, while the business is very interesting under that scenario, I don’t think it’s a good idea to buy outright quite yet. If we get continued taper tantrums, Cree could get in the price range that I think would be very acceptable.

“There is Another.” (IIVI)

I have been told over and over to never buy the second-best company, but IIVI (pronounced “two-six”) has a lot of advantages and is a leader in its own right.

IIVI is scaling meaningfully as well, with $200 million of SiC CapEx vs. Wolfspeed’s $450.

So we're investing in scaling that capability of our silicon carbide substrate, a considerable amount of our capital investment that Mary Jane referred to earlier is focused on adding equipment for silicon carbide, crystal growth, epitaxial, wafer growth, ion implantation tools and to provide a clear technology road map for electronic devices and ultimately, for modules.

This company is not only a great company within the optics space, but it also gives off a “silicon carbide for cheap” vibe. Let’s play around with a really pedantic SOTP analysis.

First, assume that the SiC business is at breakeven and consists of ~4% of sales.

Let’s value that stake at CREE’s EV/Sales today, and consider the remainder of the business as “RemainCo”.

Even just putting in 10x sales on the SiC exposure would take 1.5x turns of multiple off the remaining business lines, which are great in their own right!

Look at the 3 / 5 / 10-year results:

Think of it as owning a number of strong business lines with a SiC option layered on top.

Conclusion

Wolfspeed

Wolfspeed is the purest play on Silicon Carbide available to us in public markets. Given its place in the materials ecosystem and the likelihood of wins in SiC devices, I think it’s one of the easiest bets to make on SiC, but the valuation is hard to swallow.

Given its extreme sensitivity to interest rates, CREE could be further pummeled in the recent downturn, which has disproportionately punished high growth stocks.

At ~$90, I will close my eyes and buy a little bit. As a treat.

At $75 dollars you can start to underwrite it from a mid-term DCF perspective. That’s when you have to really give it consideration.

IIVI

We didn’t go too deep, but if you’re willing to own Wolfspeed I think you should seriously consider thinking about IIVI. It’s a fairly safe company whose shareholders can generally sleep at night (this is not medical advice). If you feel compelled to own some SiC exposure, I think IIVI is the optically cheap way to do it.

One final note: I recently took a look into my crystal ball and believe Wolfspeed will change their ticker from CREE to WOLF in the next 6 months. It hasn’t been claimed.

More Companies Next Time

Next time we’ll be looking at SiC devices alongside more focused automotive semiconductor companies. I’ll discuss ON Semi, Allegro Microsystems, NXP Semiconductor, STMicro, and Infineon.

Get excited. I think the actual SiC winners will be among this group.

Additional Reading

The CREE investor day is a must-read for SiC

Appendix

More on Silicon Carbide and its Wide Bandgap

A really helpful information session is available here on the fundamentals of semiconductor physics, but it really comes down to the difference between an insulator and a conductor. When the outer layer of electrons (orbital electrons from chemistry 101) is filled or completely empty then it is considered an insulator. In other words, that material is resistant to conducting energy.

The term ‘band gap’ refers to the distance between the conduction band and the valence band. As you would imagine, wide bandgap semiconductors have a larger distance between the conduction band and the valence band compared to regular semiconductors.

Source: Wikipedia.

Effectively, this special property makes Silicon Carbide more suitable for operating at higher temperatures, voltages, and frequencies.

Other wide bandgap materials include Gallium Nitride (GaN), Gallium Arsenide (GaA), and Indium Phosphide (InP). While these all have various uses, especially in Opticals and Lasers, SiC is most relevant for automotive.

https://www.powersystemsdesign.com/articles/are-you-sic-of-silicon-part-4/22/14760

https://en.wikipedia.org/wiki/Schottky_diode

https://www.wolfspeed.com/news/cree-acquires-infineon-rf-power-business

Very helpful and the links are super useful, thank you. Is there any chance another substrate will replace SiC? I've heard GaN as a material and you mention it above, but perhaps it doesn't work as a wide band gap material for automotive. Why would that be?